How Plastic Extruded Profiles can Save You Time, Stress, and Money.

Wiki Article

Getting The Custom Plastic Extrusion Manufacturers To Work

Table of ContentsWhat Does Custom Plastic Profiles Do?What Does Custom Plastic Profiles Mean?The 7-Second Trick For Custom Plastic Extrusion ManufacturersExamine This Report on Plastic Extruded ProfilesFacts About Custom Extrusion Manufacturer Uncovered

At Vip, we have decades of experience production thousands of special custom-made plastic extrusions in practically every form, size, and shade you can picture - https://ouo.io/Ya5yss. Our specialized depends on making plastic accounts especially for a certain application. You inform us what you require as well as we will make it, fulfilling the greatest high quality requirements.From pre-prototype to post-production, ACE has the ability and innovation to do it all. We offer large as well as little business in industries varying from automotive to clinical, with difficult product requirements to limited resistances in America, copyright, Mexico, as well as Europe. Regardless of where you are or what market you stand for, you can depend on ACE for personalized solution as well as client complete satisfaction.

That indicates fast quote solution or material referral is just a telephone call away - https://www.directorysection.com/author/k3ll3rpl4st8/. Your questions are always responded to immediately by our experienced solution team, as well as you receive the help you need without delays or confusion. Thank you for seeing our website, we are right here to help you. Please call your ACE sales agent at 414-332-8133 or email to go over items and also solutions.

Not known Factual Statements About Plastic Extrusion Companies

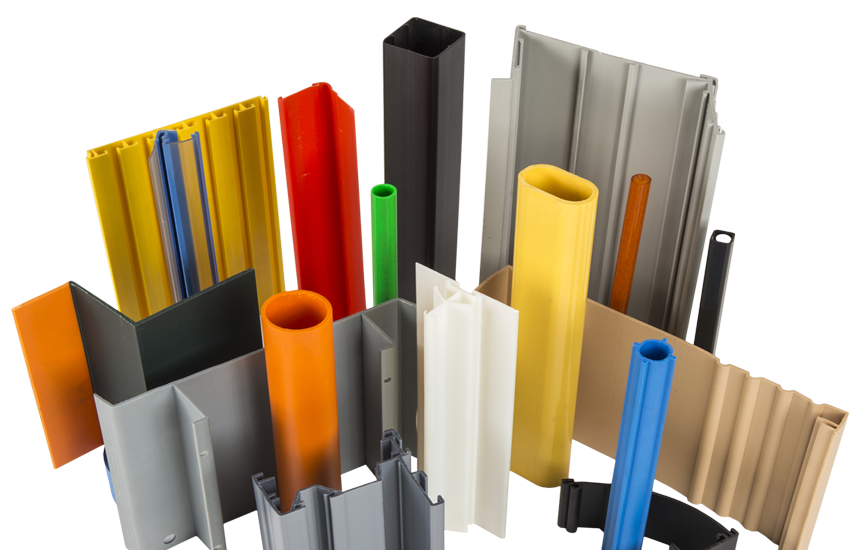

With over 100 mixed years of experience in plastic extrusion, GSH Industries is a premier B2B provider of custom-made plastic extrusions, tubes, and also plastic accounts in North Ohio. Our developers and also designers can aid you in choosing the best materials for your product line - https://site-9459215-9165-3227.mystrikingly.com/blog/keller-plastics. We have a vast selection of plastic resins and also can match any type of customized colors to your client's specifications - plastic extruded profiles.It is one of one of the most preferred methods plastic components are currently generated due to its convenience. Custom-made extrusions can be created into intricate forms of varying densities, toughness, sizes, colors, and also also textures, as well as are reasonably easy to deal with. The extrusions can additionally be formulated with performance improving characteristics such as fire resistance, enhanced durability, enhanced stamina, anti-friction or anti-static residential or commercial properties, as well as a lot more.

It can additionally possibly lead to longer cooling time with will enhance your total manufacturing time and expenses. Sharp corners and notches create weak factors in the profile where splitting or failure can happen since they moved here reduce the impact resistance of the profile by producing a high anxiety focus. Preferably, when making your account extrusion sharp edges need to be stayed clear of completely rather purpose for rounded edges.

Unknown Facts About Plastic Extrusion Companies

Ideally the distance should be equal to the wall density of the extrusion. This adds to smoother product flow during extrusion as well as much less anxiety on the account's edges. They require additional adjustments to the die to make sure appropriate product circulation, can cause unequal air conditioning, and also can create locations of weak point that can result in failing.If your component needs to have hollows, a hollow within an additional hollow is never ever a great concept. It will be required out of shape before the extrusion solidifies - https://bit.ly/3sVR9mO. If your extrusion requires functions such as legs, grooves, snap-ins, or various other items inside of the extrusion it is best to create a conveniently available opening right into the extrusion to make sure that you can better incorporate those functions.

Examine This Report about Extruded Plastic Profiles

Understanding some consumers may be unknown with our plastic profile extrusion capacities, we have actually compiled a list of questions we are frequently asked. Durometer is a measurement of the material's hardness and is determined with a gadget which is pressed against the account's surface area, causing a dial guage analysis.

Usual scales are Shore A for versatile products and Shore D for stiff compounds. Twin durometer, or co-extrusion, is the combination of 2 or even more materials of varying physical buildings right into a solitary extruded item. An example would certainly be a stiff component with adaptable fingers that could be utilized as a gasket or pillow.

Depending on the component complexity and raw materials, one could approximate the prices starting at less than $1,000. Due to differing set up expenses and run efficiencies, we try to limit the minimum production quantity to 1,000 lineal feet.

7 Simple Techniques For Custom Plastic Profiles

What causes the line. If you take a close take a look at a drawing for a plastic profile with an intersection leg, you will certainly see there is even more mass in the area of the junction. Because polycarbonate materials reduce some during the cooling process, the junction of two legs cools at a slower rate than the remainder of the profile, triggering it to reduce more because of the mass of the account.

A tool designer would typically separate the circulation of the 2 legs within the die, and enable them ahead back together as the extrudate is being compressed to the front of the extrusion pass away. This can sometimes create a weld line where both thaw streams are brought back together so cautious adjusting of the extrusion tooling is vital to lessen this line.

Report this wiki page